Building the future of autonomy

When I started at Microsoft in the early ’90s, at the dawn of the PC and Internet era, I couldn’t have imagined all of the waves of innovation that were to come. Then as well as now, I had a fundamental belief in software as a means for innovation, with which amazing ideas could be brought to life quickly.

The third industrial revolution of computing (after steam and electricity) saw the most rapid advancement in the history of mankind. It laid the foundation for the fourth industrial revolution, that of artificial intelligence. Within this, we are focused on bringing human-taught intelligence to machines that operate in the real physical world around us, bridging the world of bits to the world of atoms.

We started this journey two and half years ago with the acquisition of a startup called Bonsai and combining the team with our AirSim research effort. We were surprised to learn how little was currently being executed in the market compared with the vast potential of autonomous systems to change so many industries. The potential to help our customers innovate with this technology and bridge the divide between the physical and digital worlds is limitless.

Autonomous systems are not just about humanoid robots or self-driving cars; PepsiCo developed AI using Microsoft Project Bonsai to optimize the extruder machine, which makes Cheetos. The intelligent system continuously monitors and makes adjustments to maintain consistency and quality.

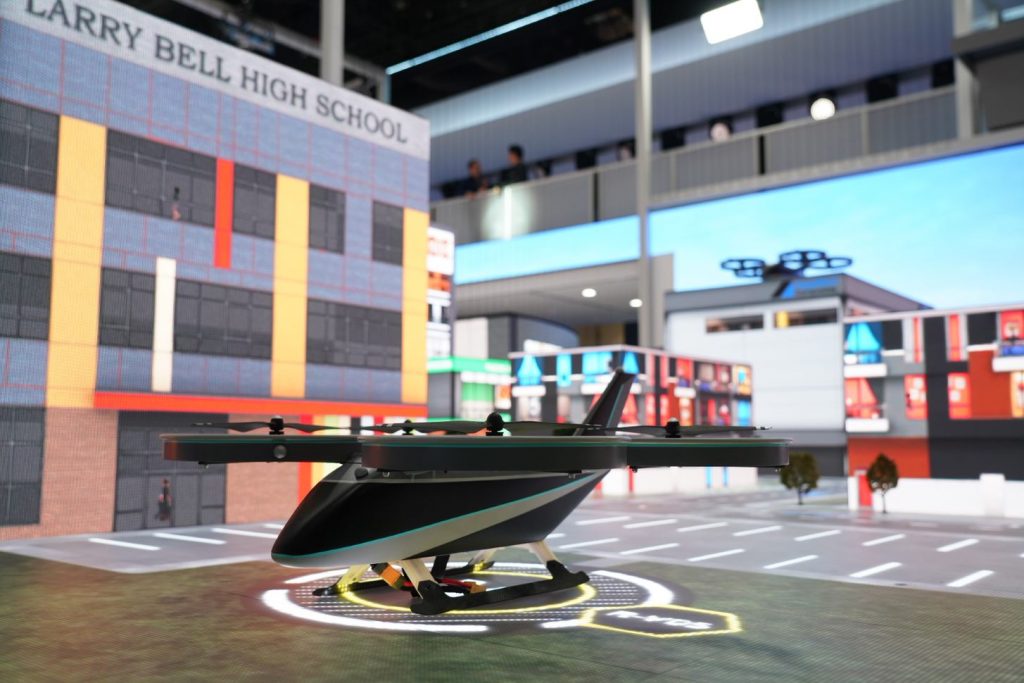

Bell is using Microsoft autonomous systems and AirSim to work toward safer autonomous flight vehicles, starting by focusing on landings. Bell is currently working toward the first autonomous precision landing using Project Bonsai to identify safe landing zones and then land autonomously.

Autonomous systems technologies are neither science fiction nor expensive moonshots – customers like PepsiCo and Bell are driving business impact today – and our software-led approach for autonomous systems is making this possible.

The most malleable medium

Software is the most malleable medium that there is. This malleability enables us to craft abstractions and layers of capability that allow creators to quickly build any type of autonomous systems that can be imagined.

Many early efforts to create autonomous systems were developed as siloed, bespoke applications by a team of experts. We knew we needed a different approach, so we looked to provide open, reusable and powerful tools and a platform that would enable anyone to teach intelligence to machines without being an AI expert. Engineers, experts in their own fields, can transfer their years of experience into an AI solution without going back to college to learn AI.

But how do you teach a machine? Most machines today are hardcoded in functionality and have basic or rigid control systems. Our tools allow an expert to express what needs to be learned and how to learn it. With that input, our platform uses reinforcement learning against a simulated environment to build the AI solution. The resulting AI solution can now control the machine and make it adapt intelligently to the real world, in the same way a human would. For example, instead of building special cages for robots, the robots learn to climb stairs, open doors, navigate a dynamic warehouse, land a drone or work together with other systems and humans.

The Bell team identified Microsoft technologies that could help them work toward their goal of transforming their business model from helicopters to autonomous flight vehicles. Along with computer vision and cloud computing from Azure, Project Bonsai and AirSim helped Bell create an AI solution that can practice in a simulated environment.

Matt Holvey, Senior Manager of Intelligent Systems at Bell, had this to say: “We’re using Project Bonsai because it allows us to quickly create and teach an AI just like if we were training a pilot on what to look for. You can get the AI to understand what decisions to make about altitude and pitch based on the identified landing zone it sees.”

Machine teaching enables any engineer to safely add autonomy to new or existing machines.

The question is not what we can imagine building, but how do we make it real?

Simulating reality

Autonomous systems operate in the real world, but the real world is not a safe place to train a machine. Also, machines are expensive. AI needs millions of cycles to learn a new skill. Imagine needing to drive tens of millions of miles in a car to learn how to drive safely on the highway!

Accurately simulating our environment, machines and sensors captures not just the visual aspects but also its physics. Once created, this simulated world can be instantiated thousands of times and allows us to “overclock” reality, thus accelerating AI training millions of times over. All this training is done safely in the cloud, where we can not only train for core scenarios but also for any possible edge case —no matter how unlikely— before operating in the real world.

Let’s take Bell, for example. It is unrealistic for unmanned aircraft to practice identifying landing zones and landing in the real world for three key reasons: safety concerns, potential damage to the aircraft and the amount of time it would take to train in enough real-world scenarios.

Instead, as Holvey from Bell tells us, the AI practices in AirSim, a simulated environment, where it can practice thousands of landing identification scenarios in minutes.

“One AI works to learn if a landing zone is safe, while another AI learns how to land,” he says. “These two AI then work in partnership to complete the complicated job.”

Simulations also enabled engineers to quickly simulate a whole day’s production. The AI experienced and learned how to make perfect Cheetos by running thousands of trials safely in simulation.

Simulations of the real world and machines enable us to safely train and teach our machines to be increasingly autonomous. You can learn more about the simulations supported in Project Bonsai and how to add your simulation running in the cloud or on-premises from the Project Bonsai documentation.

A real future

I believe that the world is ready for autonomous systems: autonomous forklifts shipping products, smart energy consumption in buildings, drones regularly inspecting power lines to prevent devastating forest fires or robots meaningfully assisting living. The question is not what we can imagine building, but how do we make it real?

By digitizing our reality with the malleable medium of software, powerful teaching tools and experiential AI, we are creating a world where autonomous systems are ubiquitous – and are having a positive impact on our planet, our economy and our lives.

Thinking about the future of autonomous systems from an alternate perspective gives us insight into a world where most mechanical things are increasingly autonomous. You can watch my video about the future of autonomous systems and dive deeper into how the technology works and how to get started.

I invite you to learn more and join us on this journey. You can experience being the plant manager who is converting plastic waste into ping pong balls in the factory of the future demo, read about the experiences of our customers, explore our industry solutions, learn about the Project Bonsai platform or try your hand at training an AI agent to balance a ping pong ball with Project Moab.

Learn more and join us on this journey:

- Project Bonsai

- Factory of the future demo

- Customer stories

- Autonomous systems Industry solutions

- Project Moab

Gurdeep Pall is Corporate Vice President for Business AI at Microsoft.