Concrete – it’s the foundation of our built environment. Chances are you can see something made of it right now, because concrete constitutes around half of all human-made things on the planet.

But cement – a core ingredient in concrete – is also a big problem for the environment. If the cement industry were a country, it would be the world’s third-largest emitter of CO2 after America and China. It produces about 8% of the world’s carbon emissions each year – substantially more than the aviation industry (which makes up around 2.5%).

And as populations and infrastructure grow, our reliance on concrete is not likely to diminish any time soon. So, how do we balance our rising demand against the urgency to tackle our greenhouse gas emissions and avoid the worst impacts of climate change?

A greener building material

Johannes Tiefenthaler recognized the problem and wanted to do something about it.

“In 2017, for the first time I visited a lecture at the University here in Zurich, where they talked about carbon capture and storage and also negative emission technologies,” he says. “And back then I would say the Paris Agreement was rather fresh. But what was surprising for me was that in the carbon capture and storage space there was not much happening, although the need to have such technologies in place was clearly there in order to meet climate goals.”

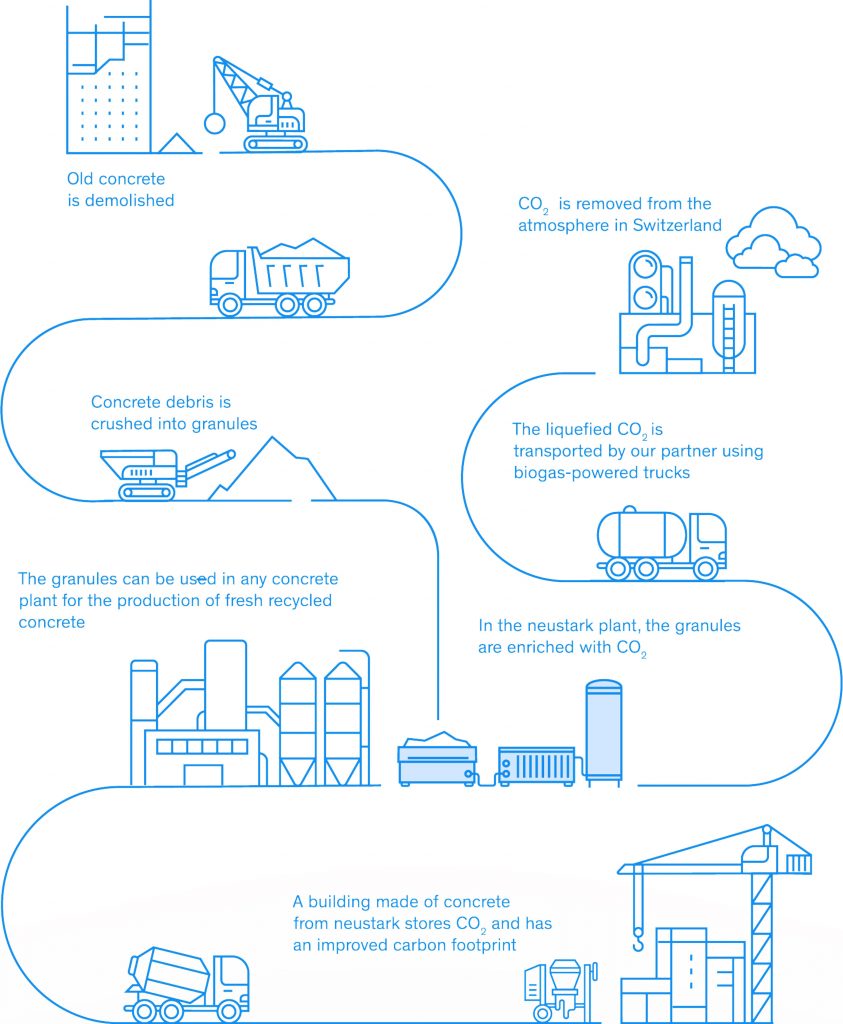

Using his academic background in chemical engineering, Tiefenthaler established neustark along with co-founder Valentin Gutknecht. The Swiss business enables the production of concrete with a difference. Carbon removed from the atmosphere is added to ground-down concrete recycled from demolition to create an end product that requires less new cement and permanently stores carbon.

Neustark is one of a number of companies attempting to decarbonize concrete production. Research by McKinsey suggests that the industry has the potential to reduce its carbon output by 75% by 2050, but the vast majority of this improvement will come through technological advances rather than operational improvements.

About 10 kg of CO2 is irreversibly stored in each cubic meter of neustark’s concrete, the company explains, and up to 20 kg of new carbon emissions are avoided in the manufacturing process. This results in concrete with a 10% improved carbon footprint.

Why we need carbon removal

Limiting climate change and reaching our environmental goals relies on us reaching net zero by 2050. But while the primary focus has to be on reducing the amount of carbon we release into the atmosphere, on its own this won’t be enough. We also need to remove carbon in order to counteract historic emissions and balance out residual emissions.

To date, the technologies available for carbon removal all have limitations, particularly around cost and permanence. It is against this backdrop that reducing the climate impact of the concrete industry stands out, offering a permanent way of tying up carbon while also tackling one of the key sources of emissions.

Promoting high-quality carbon removal solutions

Carbon mineralization such as used in neustark’s process has been identified as one of the three most promising approaches to carbon removal according to a recent report commissioned by Microsoft and completed by the Lawrence Livermore National Laboratory in the United States.

Neustark is part of the “Microsoft for Startups” program and uses Azure cloud services to manage its negative emission value chains. In addition, Microsoft has purchased neustark carbon removal alongside a number of other emerging technologies as part of its commitment to become carbon negative by 2030.

In this way, Microsoft hopes to help steer the market towards high-quality carbon removal technologies and grow the viability of these technologies.

Alongside corporate investment, Tiefenthaler also points to policies like the EU Emissions Trading System as a vital source of carbon finance to help carbon removal technologies become economically viable.

“A major challenge is that they need some help, some carbon finance like the European Emissions Trading System, which is in place,” he says. “Under such trading systems these technologies can become economically viable in the upcoming 5 to 15 years.”

Using policies to drive forward progress

Neustark is the first technology based carbon removal solution working under a gold standard verified methodology, but there are huge variations between the quality and duration of some of the removal solutions available. And without common standards and definitions sitting above them all, it is difficult to drive forward meaningful action, monitor progress, and accurately account for the carbon we emit and remove.

Without common standards and definitions… it is difficult to drive forward meaningful action.

“I think an important aspect is carbon accounting,” says Tiefenthaler. “Because what we sell is climate impact, and climate impact is a product you cannot see, you cannot feel. And for this reason, it’s very important to actually transform this climate impact into a trusted product. And this works through international carbon standards.”

This is a point Microsoft Chief Environmental Officer, Lucas Joppa, expanded on in a recent TED talk.

Carbon neutral concrete at scale

Tiefenthaler believes all concrete aggregate should go through a CO2 sequestering process in the future. His aim is for Switzerland to reach this goal in the next two or three years and expand to additional markets. The product is already being rolled out in Austria, Germany, and The Netherlands.

He argues neustark’s patented carbon removal technology has the potential to be scaled up quickly, because a lot of the infrastructure and technology needed already exists. Sequestering carbon is a comparatively small addition and cost in the concrete value chain.

And it is certainly not a solution limited by availability – there are billions of metric tons of existing concrete to be used.

However, making that vision a reality relies on having the correct support in place – both in terms of policy and regulation and willingness from companies to invest in high-quality carbon removal solutions.

“Most important for the carbon removal market is that there is actually a carbon removal market, meaning that there are customers who are interested, and who are purchasing carbon removals,” Tiefenthaler says.

“And they do not only need to purchase carbon removals which are generated right now, there needs to be a commitment over many, many years, such that companies like neustark can build value chains which aim to operate for 20 to 30 years.”