Microsoft broadens availability of autonomous systems tools for engineers and developers

When the chemical division of SCG needed to solve a complex manufacturing problem, its leaders made a bold choice: collaborate with Microsoft and use artificial intelligence to supplement its own innovation.

Why choose a technology company to help with a chemistry problem?

“Our problem was relatively complex, due to the nature of chemical processes,” said Surachate Chalothorn, CTO for Olefins and Operations of Chemicals Business, SCG. “To achieve our goal for operational excellence, having a good simulation model was not enough. We believed that chemical process simulation needed to integrate with AI technology to solve our complex problems.”

The solution the company chose was Project Bonsai, the first service component of Microsoft’s autonomous systems vision. The Microsoft investment in autonomous systems technologies is designed to empower traditional engineers, like the chemical engineers who work at SCG, to use AI to find new solutions to complex problems.

“We worked together to tackle this challenge,” said Yanon Lorpatarapong, AI Lead Engineer for Chemicals Business, SCG. “It wasn’t just buying a solution. Our team actually did the coding and contributed a lot during the project.”

Project Bonsai, now in public preview, as announced at Microsoft Build, is a machine teaching service to create and optimize intelligence for industrial control systems. Through machine teaching, subject matter experts without an AI background can break down their expertise into steps and tasks that are imparted to AI agents. The experts can specify desired outcomes and criteria, then supervise the AI agents as they work to solve problems in simulated virtual environments. The experts provide feedback and guidance that trains the AI agent to dynamically adapt within the simulation. Once they are sufficiently trained in the simulation, those AI agents can use their knowledge to power autonomous systems in real-world applications.

Traditional engineers and software developers alike can use the Project Bonsai platform to create custom solutions to their specific problems.

“This approach bridges AI science and software to the traditional engineering world, enabling fields such as chemical and mechanical engineering to build smarter, more capable and more efficient systems by augmenting their own expertise with AI capabilities,” said Mark Hammond, Microsoft general manager for autonomous systems.

Since the initial announcement of Project Bonsai, Microsoft partnered with customers on a broad range of projects within manufacturing, process control, robotics, energy, smart buildings, consumer durable goods and other sectors. Those projects informed documentation, templates and training videos that people can now access in a self-serve fashion.

“We are opening it publicly so that anyone who wants to come in and give it a spin can do so,” Hammond said. “You can come in and take advantage of the demonstration hardware, simulations and partnerships we’ve put together. You’ll be able to understand not just the theory behind how a system can help you, but actually try it yourself and find out whether it can help solve your problems directly.”

This approach bridges AI science and software to the traditional engineering world, enabling fields such as chemical and mechanical engineering to build smarter, more capable and more efficient systems by augmenting their own expertise with AI capabilities.

A collaborative solution

For a company to use Project Bonsai, it needs a simulation. Developing a simulation from scratch requires a lot of expertise in a given domain, so many companies take advantage of existing simulation software packages in connection with Project Bonsai. Customers can connect with services such as MathWorks Simulink or Anylogic and benefit from the built-in support to scale those simulations using the Azure cloud.

Thailand-based SCG had created its own simulation that the company paired with Project Bonsai to speed up its chemical manufacturing process flow.

“We put the AI model to play on our simulation and it can learn and find the way to a new operating procedure,” said Pitak Jongsuwat, Physics Model Technology Engineer for Chemicals Business, SCG. “It can play the simulation 100,000 times a day.”

SCG’s willingness to try something outside of the box is a testament to the company’s culture and initiative, according to Hammond.

“A lot of the people who are adopting Project Bonsai are the ones really trying to push the boundaries or who have tried many times to solve these problems using traditional techniques and found them intractable,” he said.

That was certainly true for SCG, who not only wanted to solve its own problems but to also continuously improve processes to remain leaders in the industry.

“Typically, we would solve chemical process problems by working with traditional players in the petrochemical industry, but [Microsoft was] one of the first pure technology companies we collaborated with and it was successful,” said Nattaphol Jariyakul, Business Development Manager for Chemicals Business, SCG.

And SCG is the first Project Bonsai customer to put the work done with Microsoft into production. Developing an optimized manufacturing process flow, which could take several months for a group of experienced engineers using traditional methods, can now be done in a week.

That optimization has always involved trial and error. SCG knew it could speed up that process and reduce waste by creating a simulation, but it needed a way to more quickly process the millions of scenarios that simulation was modeling.

“The real world is very complex and the simulators are slow because they are modeling real world complexity,” said Microsoft Senior Applied AI Engineer Kingsuk Maitra, who worked closely with the SCG team. “With Project Bonsai, we were able to use empirical or surrogate model development to accelerate training and learning.”

SCG’s Chalothorn said: “The solution enabled us to make a breakthrough to the next level in process optimization by achieving better, faster and safer operations, simultaneously. This also means better product quality, maintaining SCG’s capability and promise to deliver the best value to our customer consistently.”

Learning how to teach a machine

To assist engineers and developers in learning how to impart their existing knowledge to an AI solution, Microsoft announced at Build a new robotics kit known as Project Moab.

Project Moab is a three-armed ball balancing platform that takes a classic motion control problem and lets engineers see how the machine teaching and simulations in Project Bonsai can be applied. It also gives software developers an environment in which they can learn and experiment with simulations, Hammond said.

“We’re giving people more tools in their tool chest that they can use to expand the spectrum of problems they can solve,” Hammond said.

Project Moab is based on a basic problem: Keep a ball balanced on top of a platform held by three arms. But rather than using differential equations and other traditional ways of solving the problem, an engineer will instead teach the AI system how to balance it.

“You can very quickly take it into areas where doing it in traditional ways would not be easy, such as balancing an egg instead,” Hammond said. “The point of the Project Moab system is to provide that playground where engineers tackling various problems can learn how to use the tooling and simulation models. Once they understand the concepts, they can apply it to their novel use case.”

Simulated versions of Moab are immediately available, including both a Simulink and Python simulation model. A physical kit will be released later this year.

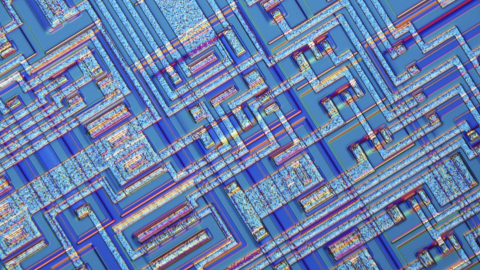

Top image: Thailand-based SCG paired Microsoft’s Project Bonsai with its own simulation to find a way to speed up its chemical manufacturing process flow. SCG photo.

Leah Culler edits Microsoft’s AI for Business and Technology blog.

Related:

- Learn more about autonomous systems

- Sign up for the Project Bonsai preview

- Learn more about Project Moab

- MathWorks and Microsoft show how to build an intelligent control system